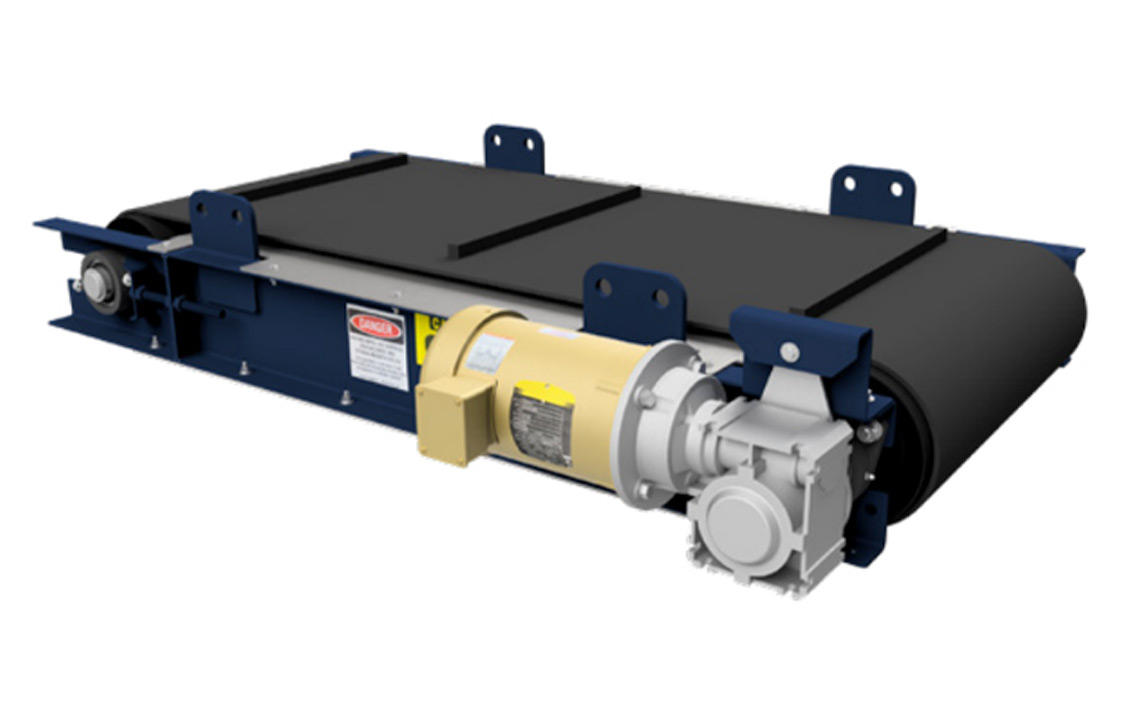

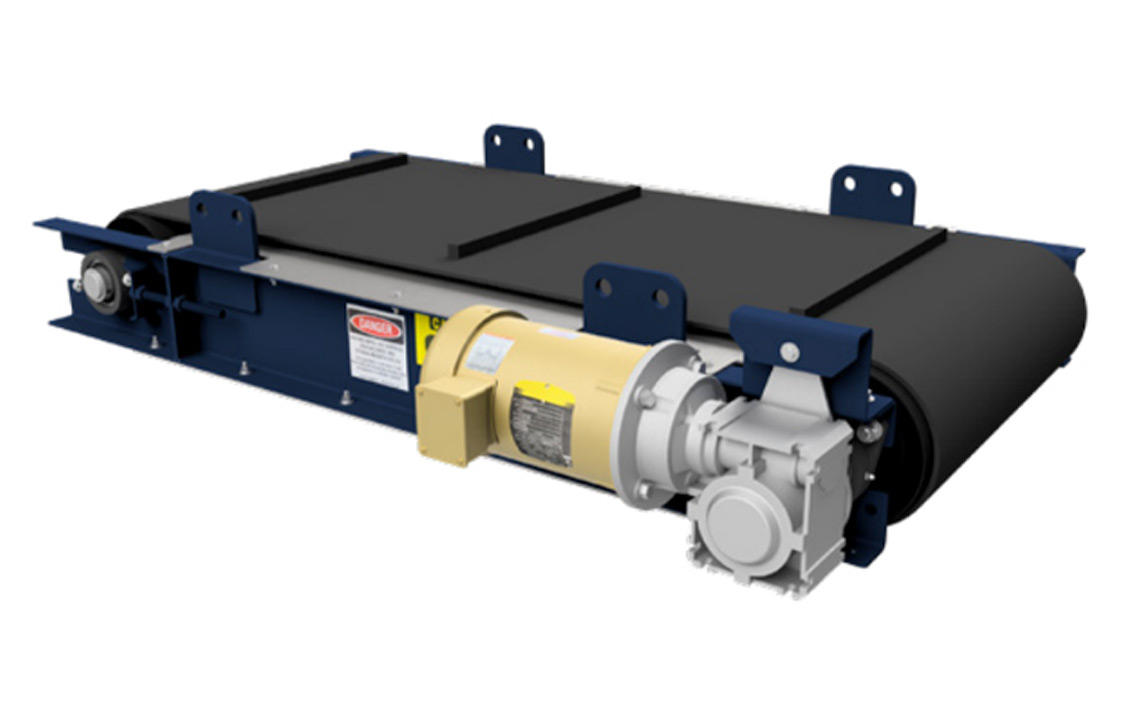

Self-Cleaning Magnetic Separator Models have a belt that continuously travels across the face of the magnet body to automatically discharge attracted ferrous metal away from the magnetic zone. These powerful models come equipped with a heavy-duty rubber belt to remove ferrous metal from the material stream. Other cleat styles and sizes are available for use in different ferrous recovery applications. To drive the magnetic belt, a direct gear motor is used and also available in special voltages.

See More From The Manufacturer

Stationary Magnetic Separator models are maintenance-free (other than maintaining oil in the electro) with no moving parts (no lubrication, no tightening or replacing of hardware needed). Ferrous metal is pulled out of the material stream to the face of the magnet and held in place until the magnet is turned off. Designed for easy installation; this model comes with a 3-point suspension system that includes two cables and one turnbuckle connected to a common bull ring. Adjustment of the magnet suspension angle is easy and only involves adjustment of the turnbuckle. There is no measuring, shortening, lengthening or cutting of cable required. These magnets are constructed with a stainless-steel bottom wear plate over the impact area.

See More From The Manufacturer

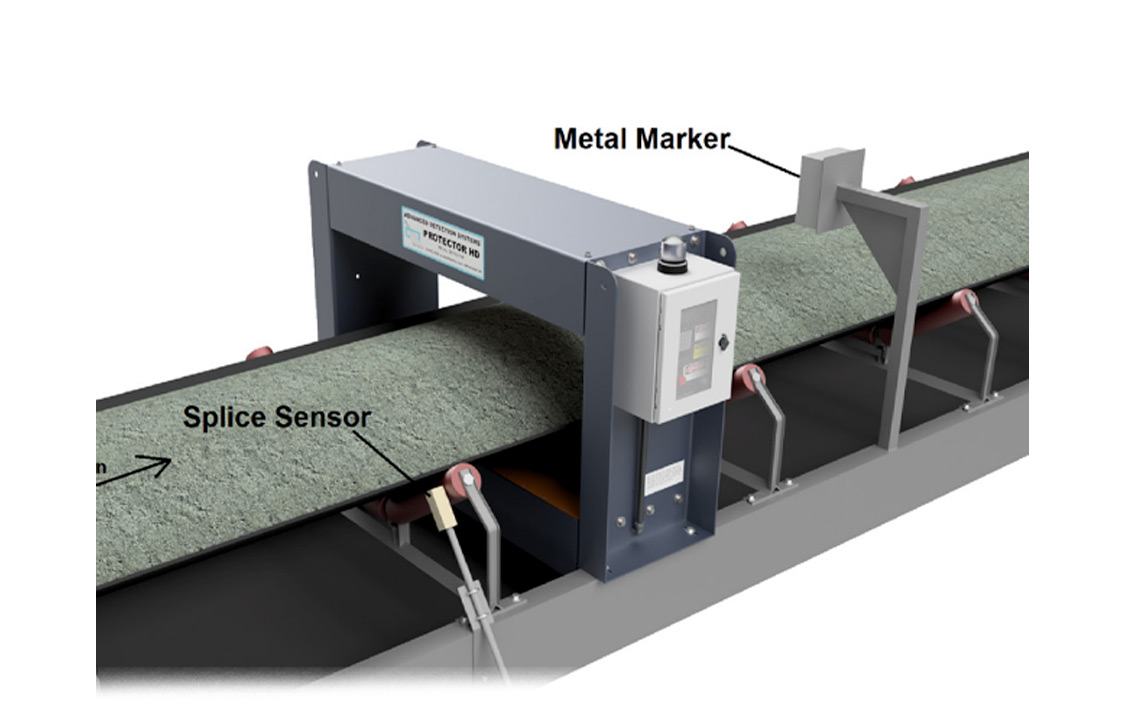

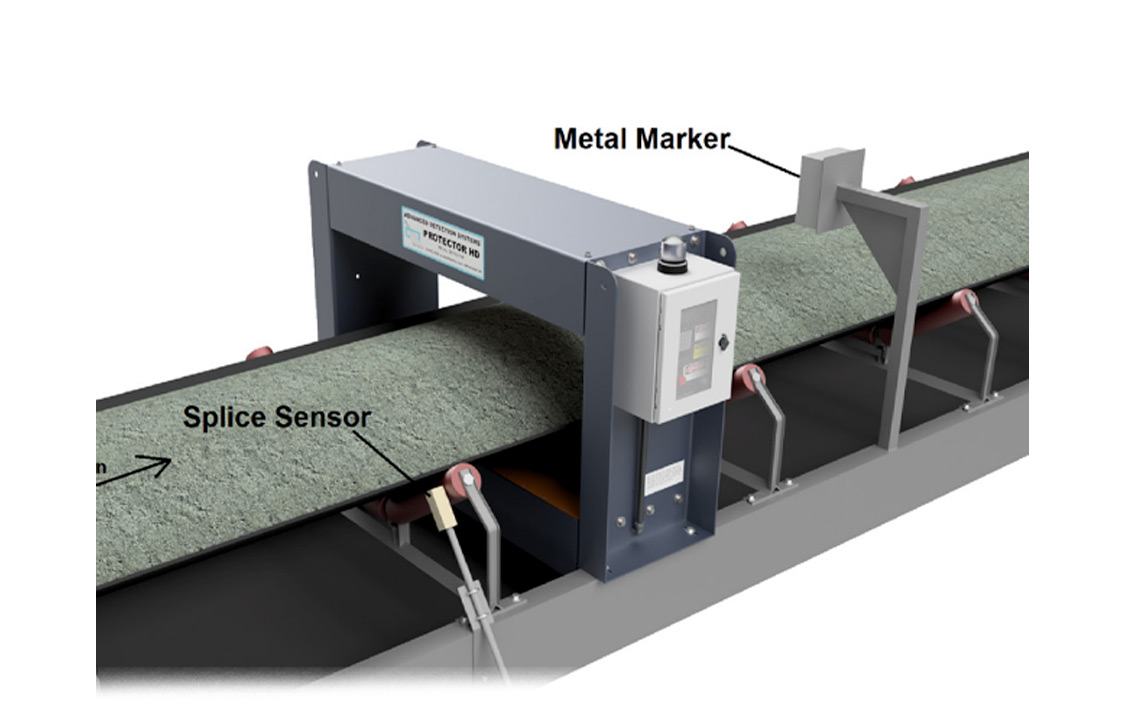

Advanced Detection Systems’ engineering, service and sales staff are industrial metal detector experts. We have experience working with many types of customers including food processing, mining, quarry and recycling trades. So whether you need to ensure product purity or defend processing equipment, Advanced Detection Systems manufactures metal detectors designed to provide reliable, easy-to-use and consistent metal detection.

See More From The Manufacturer© 2026 Crisp Industries