We offer end-to-end services, from complete pump system design to on-site support by experienced pump and fusion technicians. With access to fusion equipment and expertise in slurry and freshwater systems, we ensure seamless integration and optimal performance. Our services extend to all pump brands, offering maintenance and repairs to keep your operations running smoothly.

At Crisp Industries, we specialize in providing custom-engineered pump solutions designed to meet the rigorous demands of the aggregate and mining industries. Our Pump & Pipe Division boasts a comprehensive inventory, including pumps, HDPE pipe, fittings, hoses, and valves.

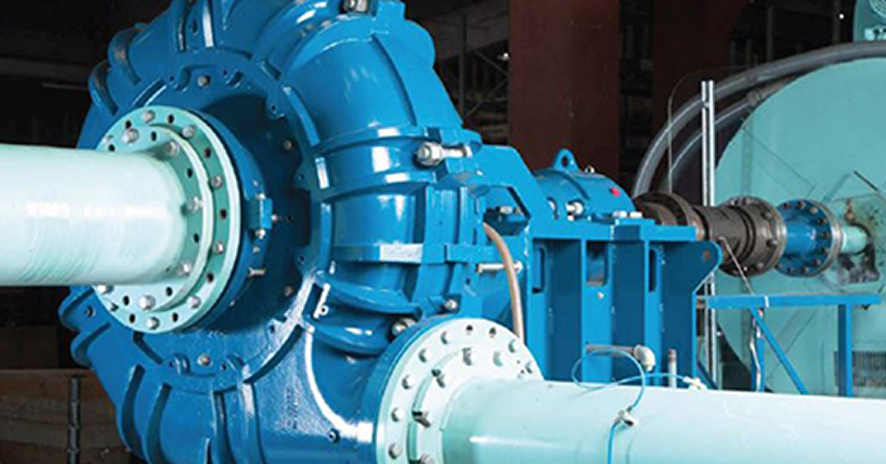

We integrate METSO pumps with HDPE piping to deliver a seamless system for efficient water movement.

Our team provides the fusion equipment, training, and support necessary to ensure long-lasting installations.

With a broad inventory of fittings, valves, and other ancillary items, we offer flexible, customizable setups for every application.

At Crisp Industries, we specialize in providing custom-engineered pump solutions designed to meet the rigorous demands of the aggregate and mining industries. Our Pump & Pipe Division boasts a comprehensive inventory, including pumps, HDPE pipe, fittings, hoses, and valves.

Crisp Industries provides custom-engineered pump solutions tailored to the demanding needs of the aggregate and mining industries. Crisp is proud to be the top North American distributor of METSO Pumps, renowned for their unmatched durability and performance. METSO slurry pumps are specifically engineered to withstand the harshest aggregate/mining conditions, excelling in handling aggressive, abrasive, and corrosive slurries.

METSO slurry pumps are the ideal choice for operations requiring high efficiency, reliability, and low maintenance. Engineered to withstand heavy-duty applications, these pumps keep processes running smoothly while helping to control costs. With their advanced design, METSO pumps deliver exceptional performance in environments where reliability is critical.

For the transport of aggressive mining slurries, METSO slurry pumps are built to provide maximum reliability. Designed to keep your processes moving, METSO pumps reduce downtime and maintenance costs, ensuring efficient slurry transport in even the toughest mining conditions.

In mining, water conservation and durability are essential. METSO heavy-duty pumps are crafted to manage both aggregate dewatering and process water applications effectively. Their robust design handles challenging slurries while ensuring minimal water loss and high performance in continuous operation.

METSO’s slurry hose and pipe systems are expertly designed for high-abrasion applications, including mill discharge, high-pressure pumps, tailings, and gravity pipes. These systems are adaptable for various plant layouts

METSO pumps offer innovative solutions to streamline sand and gravel processing, providing a cost-effective alternative to traditional trucking. By pumping sand and gravel directly from the pit into the processing plant, METSO eliminates the need for costly trucks, saving operations millions of dollars annually.

Gravel is a crucial material for building roads, bridges, and various infrastructure. METSO pumps enable the quick, efficient transfer of gravel to construction sites, reducing labor costs and boosting productivity.

In dredging, sand and gravel are essential for maintaining waterways and harbors. METSO pumps effectively remove sediment and debris from water bodies, supporting smoother dredging operations and improving navigation.

For mining, gravel is used to build access roads, haul roads, and processing facilities. METSO pumps allow for the seamless transfer of gravel and sand in mining operations, facilitating infrastructure development with less manual handling.

In flood control systems, gravel helps prevent erosion and manage water flow. METSO pumps enable the efficient placement of gravel in these applications, supporting reliable and effective flood control measures.

Gravel is often used in environmental projects, such as stormwater management, wetland and stream restoration, and oil spill cleanup. METSO pumps transport gravel smoothly and efficiently, helping to restore natural environments.

For marine construction projects like breakwaters, jetties, and offshore foundations, gravel placement is crucial. METSO pumps ensure gravel is quickly and precisely moved into place, streamlining marine construction efforts.

Pumps are built to handle slurry accumulation in sumps, ensuring optimal plant operation and preventing material buildup.

Achieve consistent flow of materials from pits and sumps to processing plants with ease.

Crisp Industries offers a variety of pump brands and works with multiple pump vendors. Contact Us Today to get more information about any pump.

At Crisp Industries, we know that efficient water management is critical for the mining and aggregate industries. From dewatering operations to the handling of tailings, our comprehensive HDPE piping systems and METSO pumps are designed for maximum reliability, durability, and efficiency. Our focus on high-density polyethylene (HDPE) pipes provides you with a solution that is corrosion-free, break-resistant, and environmentally friendly—able to withstand even the most challenging terrains, climates, and site conditions.

Crisp Industries is a leader in providing thermoplastic piping, specializing in HDPE solutions for demanding applications like mining and aggregate facilities. They stock a wide range of materials and offer custom fabrication services, aiming to deliver extended service life and reduced operational costs. With a team of experts, Crisp Industries provides tailored recommendations to help eliminate downtime and maintenance issues.

HDPE piping stands out for its leak-free, durable performance, making it a top choice in applications like natural gas, geothermal, oil, mining, and landfill systems. With a unique heat fusion process (butt fusion), HDPE pipes achieve a remarkable NO leakage rate compared to other materials, including metal. This ductile, corrosion-resistant plastic is also highly flexible, allowing cost-effective installation methods and a long, maintenance-free service life.

As an HDPE fusion equipment distributor, Crisp Industries offers used, and new options for fusion equipment. They maintain an extensive inventory of fusion equipment and parts, accompanied by expert advice and training for seamless project execution. Their problem-solving approach ensures clients get the right tools and guidance, making them a trusted partner for HDPE projects.

Our commitment to excellence and in-depth knowledge of the industry mean that you can focus on what you do best while we handle your fluid transportation needs. Reach out today to learn how our HDPE piping systems can bring long-term value to your operation.